This is going to be a rehash of previous posts that I've made on this subject. Most of the posts are down on page 5+.

http://www.democraticunderground.com/discuss/duboard.php?az=view_all&address=125x56852#56908Ok - I'll take a swing at explaining why there WASN'T a concrete core.

First, a bio. I studied civil engineering for a few years. After leaving university, I got a job at a major Architectural Engineering firm. While working there, I did work that involved me with the engineering drawing and technical specifications for the projects. And these were big projects - Sherwin Williams paint plant in Chicago, Brown & Williamson cigarette plant in Macon, GA, and several jobs for the Army Corps of Engineers in Saudi Arabia and Iran. I know my way around drawings. When that firm let me go, they recommended me to a subcontractor, who was responsible for cost estimating of these large projects. Again, drawings and specifications were a major part of my work environment.

Remember that a building has to make money for the project owner. That usually drives the architect to design a building that can be built as inexpensively as possible. If the exterior of WTC 1 & 2 were steel, adding concrete to the construction mix will add costs. You have to coordinate the disparate material properties in such a way that costs shoot up tremendously. It would be much cheaper to use steel in both the exterior and interior, using one major set of trades for the construction work.

In addition, steel and concrete have different construction methods. Concrete requires forms to maintain the shape of the pour. These forms usually require substantial bracing to keep the forms in place. There is no indication in any of the pictures of concrete forms or bracing. Also, it's not simply concrete - for you need steel reinforcing bars to provide strength. Creating the re-bar cages is a major task and requires lots of work space and people. You would see signs of re-bar cages being put together. For steel, you simply crane the pieces into place, and then bolt or weld everything together. There are lots of pictures supporting this construction method for the towers.

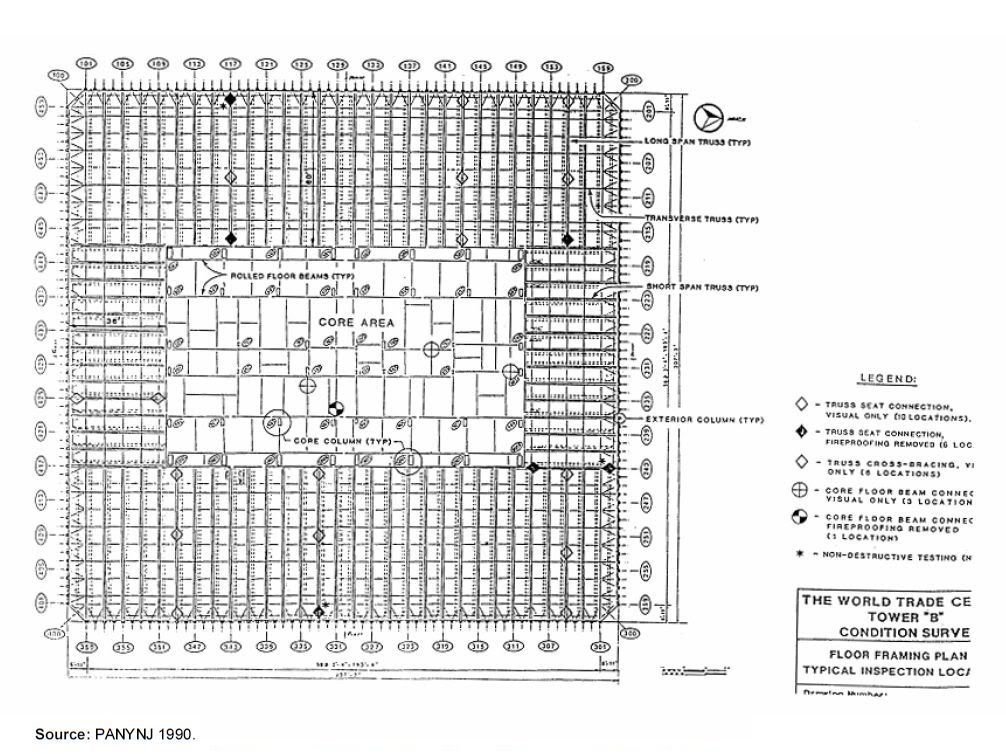

Now, this doesn't disprove the use of concrete. To do that you need to either look at the drawings, or photos of construction. The drawings were stored in the towers and were lost during the collapse. However, there are images of the drawings that show steel and no concrete. The best images I've seen in these threads are:

and:

I contend that these drawings indicate there's no room for concrete walls of the dimensions that would be required to support the building.

Still, not enough proof. So lets go to pictures. But, only after exploring how the site was prepared. The WTC site was originally covered by the Hudson River, and was reclaimed over the years. Thus, during construction, water infiltration became a show stopper. The architects designed a concrete "bathtub" to keep the water out of the site. The walls were constructed using a fairly novel technique of digging a slurry wall - basically a vertical trench that was filled with re-bar and concrete slurry, and allowed to cure. The bathtub was deep, 70 feet to bedrock if I recall correctly. It was only after the bathtub was completed that the fill of the reclaim land could be excavated, and used as fill just west of the site. In addition, there were existing subway lines that had to be kept open during the construction work. These subway tubes were supported by steel construction, not concrete.

So - pictures. Go to

http://www.nae.edu/NAE/naehome.nsf/weblinks/CGOZ-58NKUN... and download the Spring 2002 PDF version of "The Bridge". Read the article starting on page 11 titled 'World Trade Center "Bathtub": From Genesis to Armageddon'. Pay attention to the pictures. The key picture is Figure 5 on page 15, which shows the bathtub while the towers are under construction. Notice WTC 1 (top right) is substantially started. And it's supported by steel columns from the bottom of the bathtub to the street level. Also notice that there is none of the stuff needed for concrete construction. No forms, no bracing, no concrete mixers, no piles of re-bar, no re-bar cages being assembled. Nothing for concrete work.

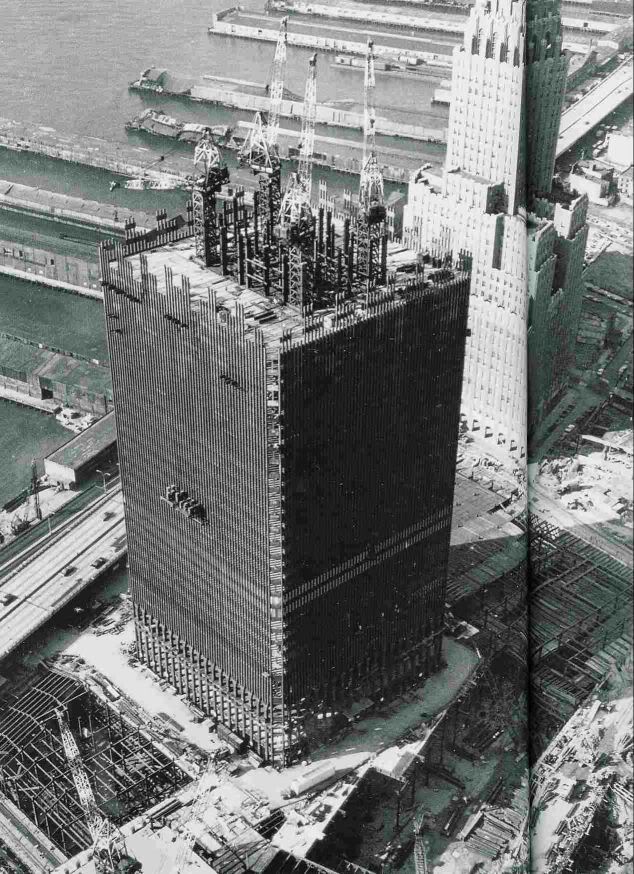

Notice that WTC 2 is just starting to come up from the bathtub floor. You can see the columns - in the layout shown in the two drawings above - just at ground level. You can also see two of the derrick supports being started. One is just above the crane in the lower left and the second is just to the left of the subway tube.

With a little mental gymnastics of rotating the picture, you can line easily line up the columns coming out of the ground to the columns show in this picture:

In looking at lots of web pages, I ran across

http://www.engr.psu.edu/ae/wtc/wtctragedy.html , which may have the mother load of links (both working and non-working). Some of the best are:

http://www.engr.psu.edu/ae/WTC/AISI/wtcaisicover.pdfhttp://www.engr.psu.edu/ae/WTC/AISI/wtcaisi1.pdfhttp://www.engr.psu.edu/ae/WTC/AISI/wtcaisi2.pdfhttp://www.engr.psu.edu/ae/WTC/AISI/wtcaisi3.pdfhttp://www.engr.psu.edu/ae/WTC/AISI/wtcaisi4.pdfhttp://www.engr.psu.edu/ae/WTC/AISI/wtcaisi5.pdfRead these - there's NO MENTION OF CONCRETE. Which is especially telling, because the documents describe how the towers WILL BE (future tense) constructed.

And

http://www.graduatingengineer.com/articles/feature/01-1... has a few nuggets. Especially the highlights:

The concept of the fire-rated shaft wall partition system, which replaced masonry and plaster walls-at the time the standard enclosure for elevators, stairs, duct shafts, etc.

and

The conception and development of a computerized system to order structural steel, and to produce structural steel shop drawings from digital information developed and provided by the firm. The adjacent New York City streets were narrow and congested, and there was little storage space available to hold the steel. Each of the 200,000 pieces of steel had to arrive in the correct order and at the right time. The computerized system was one of the industry's earliest computer-programmed control systems, the first used for structural steel procurement. It took six months to write and set up.

There has been a lot of discussion of building codes and how they relate to the WTC towers designs. Remember that a revision of building codes don't just "spring into existence", they require years of preparation to put into place. The industry comments on how the codes need to change long before the code becomes "The Code". The building code of 1968 was a vast change - away from a "you must do it this way" to "this is what we want". Fire protection is an excellent example. The old code required masonry (brick, block, etc) to surround steel columns to provide fireproofing. The new code required that the steel should stand fire temperatures for certain periods of time. Thus, spray on fireproofing came into use.

A good discussion of how building codes and construction methods may have played a part in the collapse can be read here:

http://vincentdunn.com/wtc.htmlA couple of miscellaneous points:

1. Where did the 47 1,300 foot columns go? Simple - they broke apart just like the exterior wall spandrels did. All material had to be brought through the narrow streets of downtown Manhattan. There's no way a 1,300 foot column could be assembled, except through assembling many smaller columns. Also, you don't see 47 1,300 foot columns stick out of the top of this picture:

Those columns were assembled on site. Remember, the exterior wall was assembled in place, and so would the core columns.

2. There have been comments that the concrete floors couldn't break apart until they hit the ground. Nonsense. There was so much material (columns, elevators, desks, everything in a building) being jumbled up that there had to be impacts. Simple experiment. Take two rocks & throw them together in the air. I'll bet if you can get the rocks to hit hard enough, some material will break off.

3. Many comments have been made upon eye witnesses talking about concrete encased stairwells. I would expose that people under stress wouldn't remember what the stairwell walls were made of. However, there are several reports where someone used simple tools to claw their way through gypsum wallboards and to escape the stairwells. I believe the 1968 code started the use of firewall rated gypsum boards to enclose stairwells.

4. Explosions. I have no doubt that there were explosive sounding events as described. I've heard explosions also - as the car across the street burned to the ground. Lots of things make loud popping noises when they fail - car windows, car tires, batteries, etc. Just because an explosion was heard doesn't mean it was caused by explosives.

Finally, I referenced the spring 2002 article in "The Bridge" and the article on the bathtub construction. The article just prior to that is by Leslie Robinson - the structural engineer on WTC. Read that article - there is NO MENTION OF CONCRETE outside of the bathtub wall.

Finally, if this diagram is correct:

with a solid concrete core fitting inside the inner core columns, how could you be able to see through the building as seen in:

If anything, the central core would be a solid obstruction, with hallways every other floor. That's simply not what you're seeing in this picture.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Christophera -

I don't want to make this personal. I don't know you. You don't know me. Maybe we'd be friends if we met in real life, maybe not.

The first site plan is obviously rotated to fit the orientation of paper. The arrow points to what is called "site north", which doesn't necessarily point to true or magnetic north. A "site north" just makes it easier for people working on the project to orient themselves. You do know that New Yorkers say "go north on Fifth", while they actually go Northeast by East. It's a convenience to people.

The UK diagram of the building is a joke. It's a shame that something put together shortly after the collapses is still around when that diagram doesn't look anything like the multiple pictures taken during actual construction.

Who says steel flexes too much? According to this

http://www.engr.psu.edu/ae/WTC/AISI/wtcaisi5.pdfthey were using 12 different strengths of steel. And it's fairly easy to engineer for any flex of the steel. Besides, steel riggers are well aware of how steel changes shape during storage and erection.

I can't refute or accept your argument on how the floors had different hallway configurations. Can you provide links to this information?

Also, go look at

http://guardian.150m.com/wtc/godfrey.htmPlenty of references to steel. None for concrete.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

I think the mysterious PBS documentary has been found.

And there's no mention of a concrete core. But lots of discussion and pictures of steel. And steel. And even more steel.

http://primetimetv.about.com/gi/dynamic/offsite.htm?zi=1/XJ&sdn=primetimetv&zu=http%3A%2F%2Fwww.pbs.org%2Famex%2Fnewyork%2Fsfeature%2Fsf_building.htmlThis is the 1983 PBS documentary, divided into three segments. Part two has the most interesting parts, in relation to the core discussion. At about 3/4 of the way through, there is a clip where the exterior cladding is being installed. If you look closely at those scenes, you can see on the left hand side of the picture open daylight to the other side of the tower. There certainly isn't a concrete core blocking the view. In fact, since the same floor space is open on two floors, the argument that the hallways alternated on the floors can be disproved.

Elsewhere in the clip, there are many shots of the pre-fabbed floor segments being lifted into place. As the scenes change, you can easily see the truss structure underneath the decking steel.

Additionally, in the interview on

http://www.pbs.org/wgbh/nova/wtc/above.html where a survivor from the 84th floor of WTC 2 discusses evacuation. Notice that he specifically mentions his floor had criss crossing hallways in the center core. Also, he specifically mentions breaking through the dry wall of the stairwell at the 81st floor. He mentions later in the article that drywall had been blown off the wall and was blocking the stairs.

WTC 1 and 2 were built of structural steel. There wasn't a concrete core in either building.