Welcome to DU!

The truly grassroots left-of-center political community where regular people, not algorithms, drive the discussions and set the standards.

Join the community:

Create a free account

Support DU (and get rid of ads!):

Become a Star Member

Latest Breaking News

General Discussion

The DU Lounge

All Forums

Issue Forums

Culture Forums

Alliance Forums

Region Forums

Support Forums

Help & Search

Environment & Energy

Related: About this forumFood Additive Key to Environmentally Friendly, Efficient, Plastic Solar Cells

https://news.ncsu.edu/2016/09/green-solar/[font face=Serif][font size=5]Food Additive Key to Environmentally Friendly, Efficient, Plastic Solar Cells[/font]

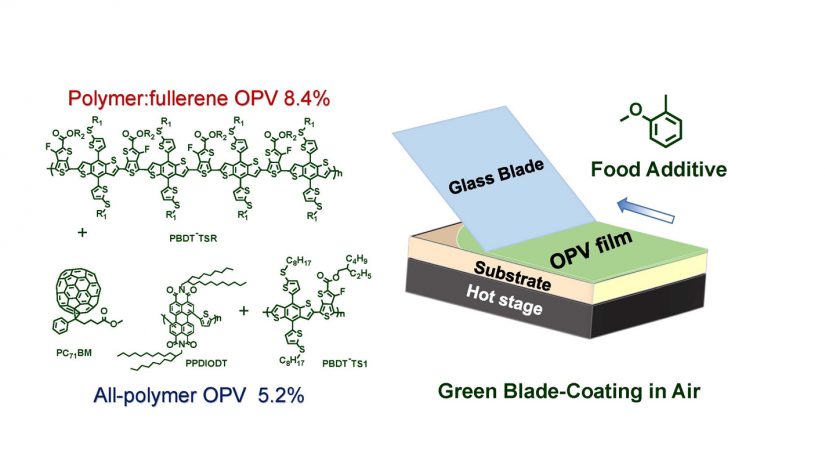

Schematic illustration and chemical structure of semi-printed plastic solar cells in air, using food additive o-MA as solvent.

Image credit: Long Ye, NC State

[font size=4]For Immediate Release

September 29, 2016

Tracey Peake[/font]

[font size=3]Researchers from North Carolina State University and the Chinese Academy of Sciences have created an efficient, semi-printed plastic solar cell without the use of environmentally hazardous halogen solvents. These solar cells can be manufactured at room temperature, which has implications for large-scale commercial production.

Plastic solar cells, or organic photovoltaics, are popular because they are lightweight, flexible, transparent and inexpensive to manufacture, making them useful in multiple applications. Unfortunately, the halogen-containing solvents used in their manufacture are an obstacle to large-scale commercialization. These solvents are key to making sure that the solar cell’s morphology, or structure, maximizes its energy efficiency; however, they are environmentally hazardous. Additionally, the use of these harsh chemicals requires a controlled environment, which adds to production costs.

Long Ye, a postdoctoral research scholar in physics at NC State and lead author of a paper describing the work, wanted to find out if nontoxic solvents could provide equally efficient morphology in the manufacturing process. Ye and his colleagues developed a proof of concept semi-printed plastic solar cell that utilized o-methylanisole (o-MA) as the solvent. O-MA is a commonly used flavoring agent in foods, and is nontoxic to humans.

The researchers used soft X-ray techniques to study the morphology of their solar cell. They found that the o-MA based solar cell had similar morphology, crystalline features and device performance to those produced by halogenated solvents. The solar cell’s overall efficiency rating was around 8.4 percent. Furthermore, their cell could be produced via blade coating at ambient, or room temperature. Blade coating is a process that uses a glass blade to spread a thin layer of the photovoltaic film onto either a rigid or flexible substrate, and the process is compatible with large-scale commercial manufacturing.

…[/font][/font]

http://dx.doi.org/10.1021/acs.chemmater.6b03083

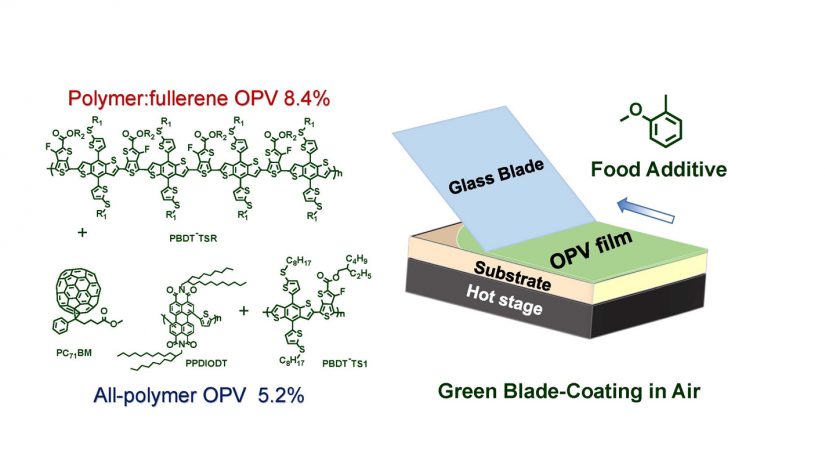

Schematic illustration and chemical structure of semi-printed plastic solar cells in air, using food additive o-MA as solvent.

Image credit: Long Ye, NC State

[font size=4]For Immediate Release

September 29, 2016

Tracey Peake[/font]

[font size=3]Researchers from North Carolina State University and the Chinese Academy of Sciences have created an efficient, semi-printed plastic solar cell without the use of environmentally hazardous halogen solvents. These solar cells can be manufactured at room temperature, which has implications for large-scale commercial production.

Plastic solar cells, or organic photovoltaics, are popular because they are lightweight, flexible, transparent and inexpensive to manufacture, making them useful in multiple applications. Unfortunately, the halogen-containing solvents used in their manufacture are an obstacle to large-scale commercialization. These solvents are key to making sure that the solar cell’s morphology, or structure, maximizes its energy efficiency; however, they are environmentally hazardous. Additionally, the use of these harsh chemicals requires a controlled environment, which adds to production costs.

Long Ye, a postdoctoral research scholar in physics at NC State and lead author of a paper describing the work, wanted to find out if nontoxic solvents could provide equally efficient morphology in the manufacturing process. Ye and his colleagues developed a proof of concept semi-printed plastic solar cell that utilized o-methylanisole (o-MA) as the solvent. O-MA is a commonly used flavoring agent in foods, and is nontoxic to humans.

The researchers used soft X-ray techniques to study the morphology of their solar cell. They found that the o-MA based solar cell had similar morphology, crystalline features and device performance to those produced by halogenated solvents. The solar cell’s overall efficiency rating was around 8.4 percent. Furthermore, their cell could be produced via blade coating at ambient, or room temperature. Blade coating is a process that uses a glass blade to spread a thin layer of the photovoltaic film onto either a rigid or flexible substrate, and the process is compatible with large-scale commercial manufacturing.

…[/font][/font]

InfoView thread info, including edit history

TrashPut this thread in your Trash Can (My DU » Trash Can)

BookmarkAdd this thread to your Bookmarks (My DU » Bookmarks)

3 replies, 608 views

ShareGet links to this post and/or share on social media

AlertAlert this post for a rule violation

PowersThere are no powers you can use on this post

EditCannot edit other people's posts

ReplyReply to this post

EditCannot edit other people's posts

Rec (5)

ReplyReply to this post

3 replies

= new reply since forum marked as read

Highlight:

NoneDon't highlight anything

5 newestHighlight 5 most recent replies

= new reply since forum marked as read

Highlight:

NoneDon't highlight anything

5 newestHighlight 5 most recent replies

Food Additive Key to Environmentally Friendly, Efficient, Plastic Solar Cells (Original Post)

OKIsItJustMe

Oct 2016

OP

WhiteTara

(29,708 posts)1. K&R

underpants

(182,799 posts)2. All of Clarke Griswold's work is finally paying off

Cicada

(4,533 posts)3. Thank you researcher Long Ye!

Is science great or what?